Centrum Machinationis Horizontale HMC-80W

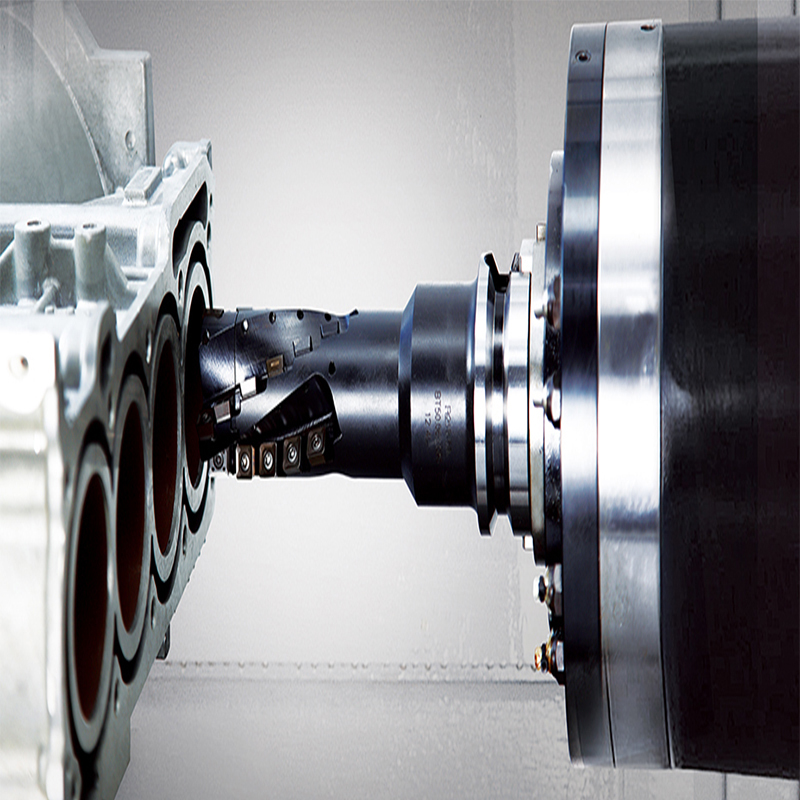

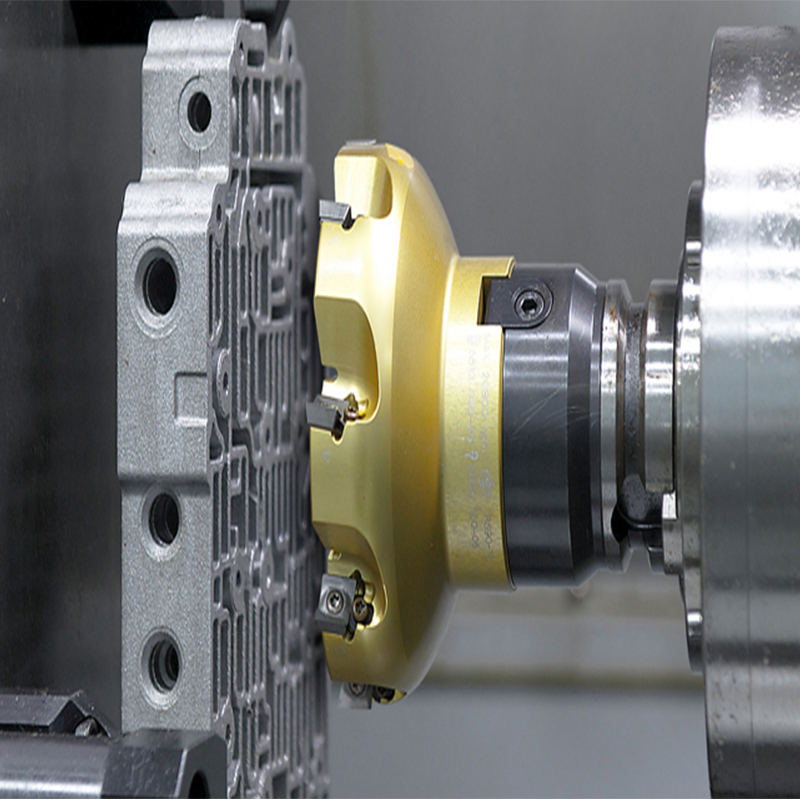

Machina fresatoria horizontalis. Haec machina perforationem, fresaturam, terebrationem, expansionem, alesationem, perforationem aliasque partes complexas sub una prehensione perficere potest, ut variarum partium complexarum, ut discorum, laminarum, testarum, cammarum, et formarum. Duae lineae et una structura dura, apta ad productionem singularum partium et massalem variarum partium complexarum in variis industriis.

Usus producti

Centrum machinationis horizontale, late adhibitum in industria autocinetica, aëronautica, machinarum generalium aliisque

Centrum machinationis horizontale. Aptissimum ad magnos ictus et partes complexas et accuratas tractandas.

Centrum machinationis horizontale, aptum ad superficies multi-operatorias et processus partium multi-processuales

Centra machinationis horizontalia late in partibus complexis adhibentur. Processu superficierum et foraminum.

Centra machinationis horizontalia late in partibus complexis adhibentur. Processu superficierum et foraminum.

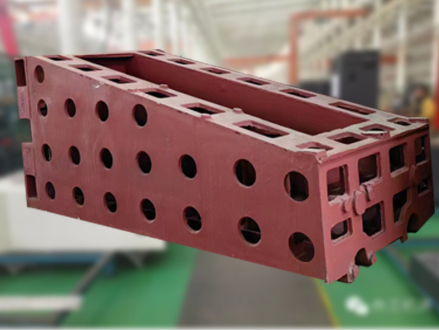

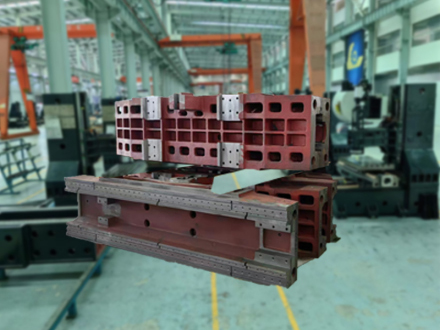

Processus fundendi productum

Centrum machinationis CNC horizontale, fusura processum fusionis Meehanite adhibet, et titulus est TH300.

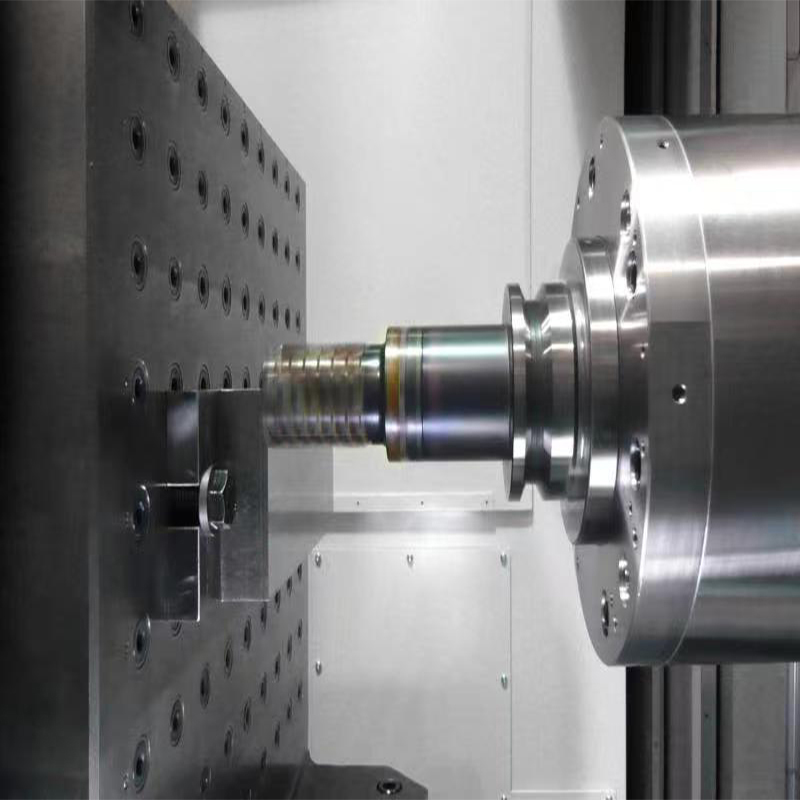

Machina fresatoria horizontalis, cum mensa et basi transversali, ad sectionem gravem et motum rapidum occurrendum

Machina fresatoria horizontalis, pars interior fusa structuram costae duplici pariete in formam craticulae adoptat.

Machina fresatoria horizontalis, lectus et columnae naturaliter deficiunt, praecisionem centri machinatorii augentes.

Centrum machinationis horizontale, designatio optima quinque partibus fusis maioribus, dispositio rationabilis

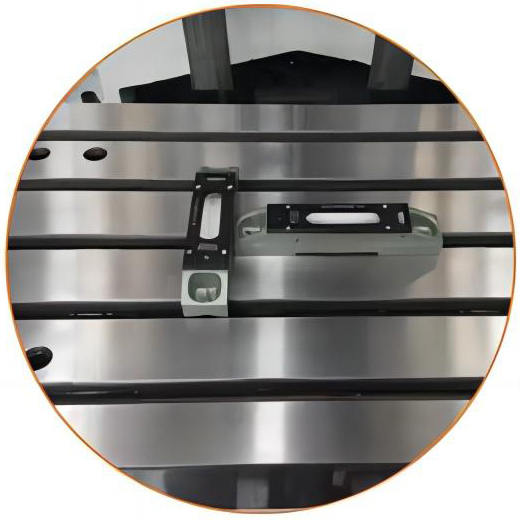

Partes Boutique

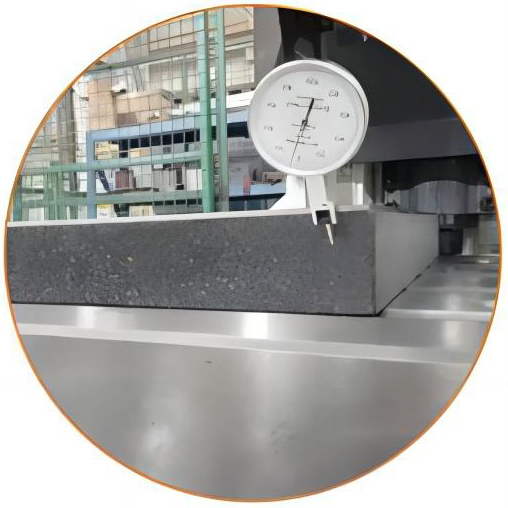

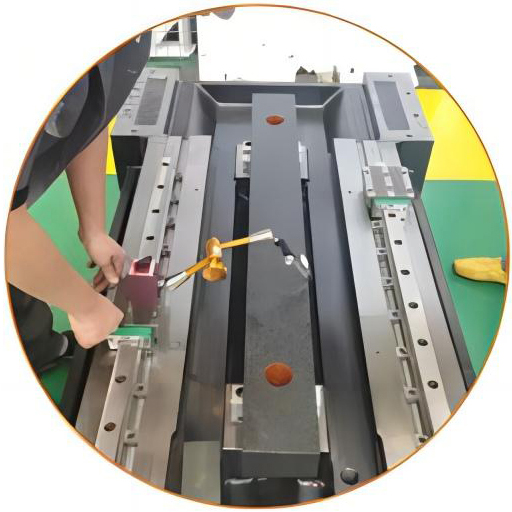

Processus inspectionis moderationis accuratae congregationis

Examen Accurationis Mensae Operis

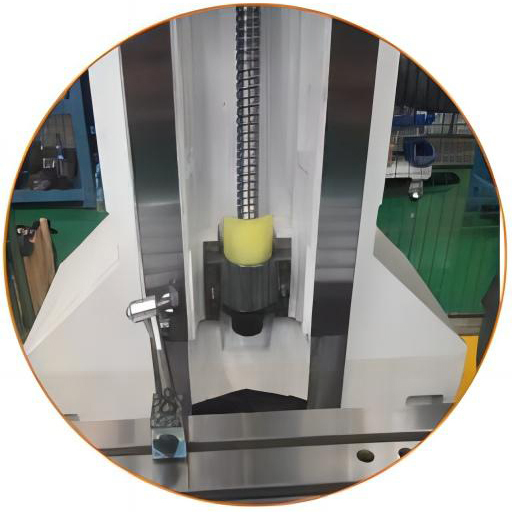

Inspectio Componentium Opto-Mechanicarum

Detectio Verticalitatis

Detectio Parallelismi

Inspectio Accuratae Sedis Nucis

Detectio Deviationis Anguli

Systema CNC notae configurandum

Machinae TAJANE, secundum necessitates emptorum, varias marcas systematum CNC praebent ut variis necessitatibus emptorum pro centris machinationis verticalibus, FANUC, SIEMENS, MITSUBISH, SYNTEC, satisfaciant.

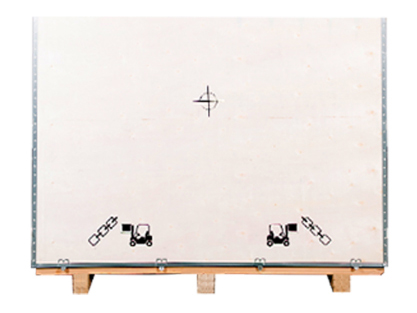

Involucrum omnino inclusum, comitatus ad transportationem

Involucrum ligneum omnino inclusum

Centrum Machinationis Horizontale HMC-80W, involucro omnino incluso, comitatu ad transportandum

Involucrum vacuum in arca

Centrum Machinationis Horizontale HMC-80W, cum involucro vacuo humiditati resistente intra capsam, aptum ad transportationem longam distantiam

Nota clara

Centrum Machinationis Horizontale HMC-80W, cum signis perspicuis in capsa involucri, iconibus onerandi et exonerandi, pondere et magnitudine exemplaris, et alta recognitione.

Fulcrum inferius ligneum solidum

Centrum Machinationis Horizontale HMC-80W, fundus arcae involucri ex ligno solido factus est, quod durum et non labentem est, et ad res claudendas figitur.

| Specificationes | HMC-80W | |||

| Iter | Axis X, Axis Y, Axis Z | X: 1300, Y: 1000, Z: 1050mm | ||

| Nasus Fusi ad Palletam | 150-1200mm | |||

| Centrum Fusi ad Superficiem Pallettae | 90-1090mm / 0-1000mm | |||

| Mensa | Magnitudo Mensae | 800X800mm | ||

| Numerus Mensae Operis | 1(OP:2) | |||

| Configuratio Superficiei Mensae Operis | M16-160mm | |||

| Onus Maximum Mensae Operis | 2000kg / 1300kg | |||

| Minima Unitas Ordinis | 1° (OP: 0.001°) | |||

| Fusus | Conus Fusus | BT-50 | ||

| Genus Aurigandi | Typus Cinguli | Typus Directus | Caput rotarum | |

| RPM fusi | 6000 rpm | Octo milia revolutionum per minutum | 6000 rpm | |

| Moderator et Motor | 0IMF-ß | 0IMF-α | 0IMF-ß | |

| Motor Fusilis | 15/18.5 kW (143.3 Nm) | 22/26 kW (140 Nm) | 15/18.5 kW (143.3 Nm) | |

| Motor Servo Axis X | 3kW (36Nm) | 7kW (30Nm) | 3kW (36Nm) | |

| Motor Servo Axis Y | 3kW (36Nm)BS | 7kW (30Nm)BS | 3kW (36Nm)BS | |

| Motor Servo Axis Z | 3kW (36Nm) | 7kW (30Nm) | 3kW (36Nm) | |

| Motor Servo Axis B | 2.5kW (20Nm) | 3kW (12Nm) | 2.5kW (20Nm) | |

| Frequentia Alimentationis | 0IMF-ß | 0IMF-α | 0IMF-ß | |

| Celeris Axis X. Z | 24m/min | 24m/min | 24m/min | |

| Celeris Axis Y Frequentia Alimentationis | 24m/min | 24m/min | 24m/min | |

| XY Z Maxima Frequentia Secandi | 6m/min | 6m/min | 6m/min | |

| ATC (Aeroportus Turistici) | Typus Brachii (Instrumentum ad Instrumentum) | 30T (4.5 sec) | ||

| Instrumenti Manubrium | BT-50 | |||

| Diameter Instrumenti Maximus * Longitudo (adiacens) | φ200*350mm (φ105*350mm) | |||

| Pondus Instrumenti Maximum | Quindecim chiliogrammata | |||

| Accuratio Machinae | Accuratio Positionis (JIS) | ± 0.005mm / 300mm | ||

| Accuratio Positionis Repetitionis (JIS) | ± 0.003mm | |||

| Alii | Pondus Approximatum | A: 16500kg / B: 17000kg | ||

| Mensura Spatii Pavimenti | A: 6000*5000*3800mm B: 7000*5000*3800mm | |||

Accessoria Ordinaria

● Ostentatio oneris fusi et motoris servo

●Praesidium contra onerationem fusi et servomotoris

●Ictus rigidus

● Tegumentum protectivum omnino inclusum

● Rota manualis electronica

● luminaria

●Duplex spiralis convector frustulorum

●Systema lubricationis automaticae

●Thermostatum arcae electricae

● Systema refrigerationis instrumenti fusi

● Interfacies RS232

●Sclopeta aerea

● Purgator coni fusi

●Arca instrumentorum

Accessiones Optionales

● Instrumentum detectionis regulae craticulae trium axium

●Systema mensurae operis

●Systema mensurae instrumentorum

●Refrigeratio interna fusi

● Mensa rotatoria CNC

●Convector catenae frustulorum

● Instrumenti longitudinem constituens et marginis inveniens

●Separator aquae

●Instrumentum refrigerationis aquae fusi

●Functio interretialis